VZET Photoelectric Sensor

A photoelectric sensor is a device that detects objects by leveraging light signals, accurately identifying their presence, position, color, or distance.

Message Inquiry

Product Details

1. Product Overview

A photoelectric sensor is a device that detects objects by leveraging light signals, accurately identifying their presence, position, color, or distance. It operates by emitting light beams and capturing changes in reflected or transmitted light, providing efficient and reliable detection solutions across diverse industries such as industrial automation, robotics, security, and consumer electronics.

2. Core Principle

(1) Light Emission & Reception

● Transmitting End: Equipped with an LED or laser diode as a light source, emitting various light beams (e.g., visible light, infrared light).

● Receiver: Utilizes photosensitive components (e.g., phototransistors, photodiodes) to capture optical signals.

● Signal Processing: Converts optical signals into electrical signals, analyzes light intensity changes via internal circuits, and triggers output signals (e.g., switch signals).

(2) Detection Logic

When an object interrupts or reflects the light beam, it alters the light intensity detected by the receiver. The sensor interprets these changes to determine the object’s position or state.

3. Product Types

(1) Through-Beam (Opposed Mode)

● Working Principle: The transmitter and receiver are separate. Detection is triggered when an object blocks the light beam between them.

● Features:

● Ultra-long detection distance (up to 100 meters).

● Strong anti-interference capability.

● Requires separate installation of transmitter and receiver.

(2) Retroreflective (Reflective with Retroreflector)

● Working Principle: The transmitter and receiver are integrated in one unit. The emitted light is reflected back by a retroreflector; detection occurs when an object blocks the reflected beam.

● Features:

● Simple installation, suitable for medium-range detection (up to several meters).

(3) Diffuse Reflective

● Working Principle: Detects light diffusely reflected from the object’s surface without a separate retroreflector.

● Features:

● Single-sided installation.

● Shorter detection range (typically several centimeters to meters).

● Detection accuracy depends on object color and surface texture.

(4) Fiber Optic

● Working Principle: Uses optical fibers to transmit light signals, enabling miniaturized sensor heads.

● Features:

● Excellent resistance to electromagnetic interference, high temperatures, and corrosion.

● Ideal for confined spaces or harsh environments.

(5) Color/Mark Sensor

● Working Principle: Identifies colors or specific markings by analyzing the wavelength or intensity of reflected light.

● Applications: Commonly used in printing quality inspection, label positioning, and similar scenarios.

4. Key Performance Parameters

● Detection Distance: The maximum range where the sensor operates stably and reliably.

● Response Time: The time from object detection to signal output (typically in microseconds).

● Light Source Types: Options include infrared (high anti-interference), red visible light (easy calibration), and laser (high precision).

● Output Types: Supports NPN/PNP switch signal outputs.

5. Usage Precautions

(1) Environmental Interference

● Avoid direct exposure to strong light (e.g., sunlight may interfere with infrared sensors).

● Use modulated light sensors to enhance anti-interference capability.

(2) Object Characteristics

● Transparent or highly reflective objects may require filter-type sensors or coding controller adjustments.

(3) Installation & Calibration

● For retroreflective sensors, ensure precise alignment of the transmitter and receiver.

● For diffuse reflective sensors, account for background objects that may affect detection.

(4) Maintenance

● Regularly clean the lens or fiber optic end face to prevent dust from reducing detection sensitivity.

6. Common Issues & Solutions

|

Issue |

Possible Causes |

Solutions |

|

Mistriggering |

Environmental light interference |

Adjust sensor sensitivity or enable filtering in the controller. |

|

Unstable Detection |

Uneven object surface reflection |

Switch to a retroreflective photoelectric sensor. |

|

Failure to Detect Transparent Objects |

High light transmittance |

Use a diffuse reflective photoelectric sensor. |

|

Response Delay |

Inadequate sensor response time |

Select a sensor with microsecond-le |

Company Reality

Wuhan VZ Information Technology Co., Ltd., established in 2018 , and located in Wuhan, China with convenient transportation accesses , is a professional company engaged in the sale and service of mini color inkjet printers, inkjet printers, continuous inkjet printers, laser marking machines, and the relevant ink consumables. We have a wide range of coding and marking machines to meet customers' different needs in their applications and at the same time, we are making great efforts to develop new products to meet different requirements. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices.

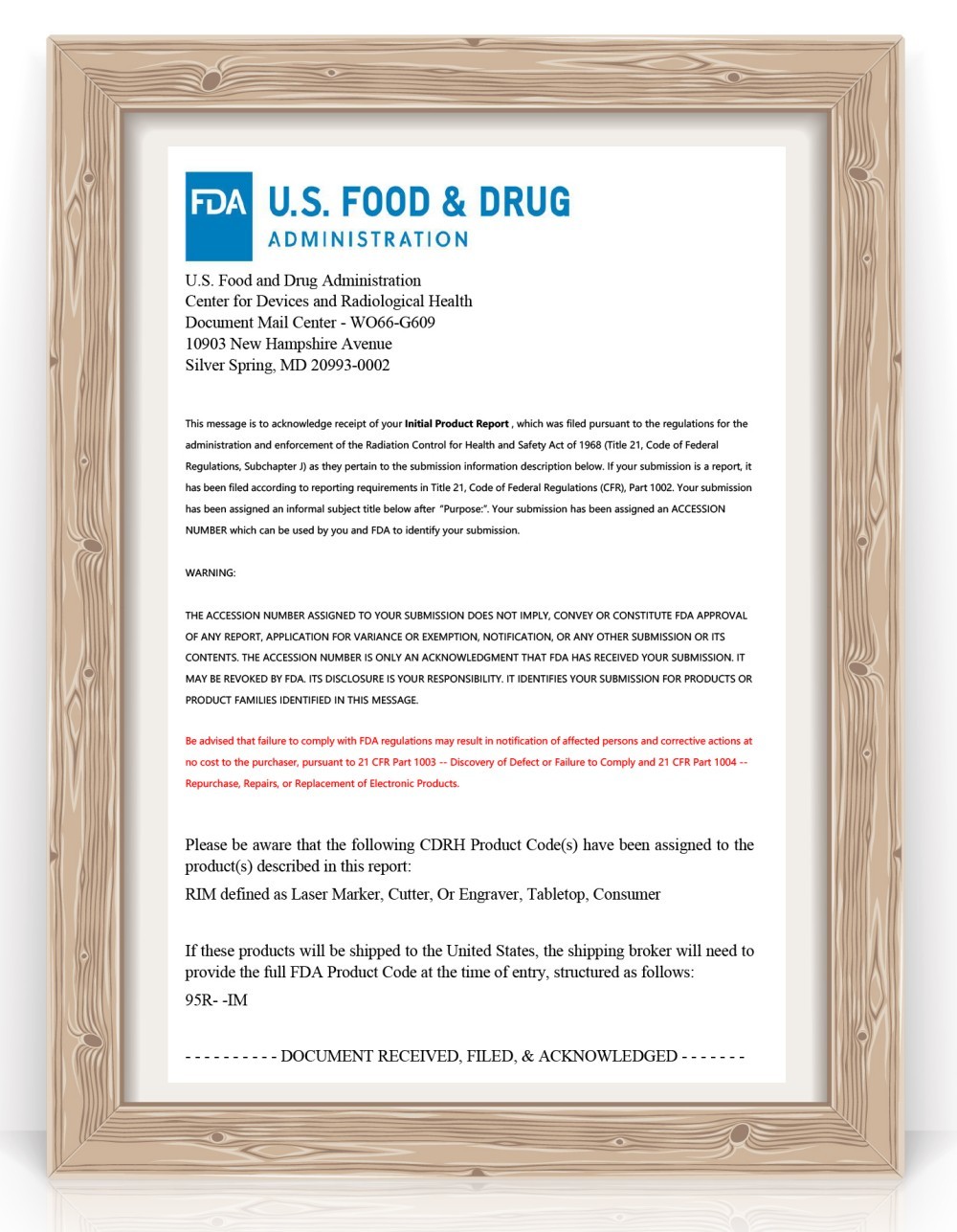

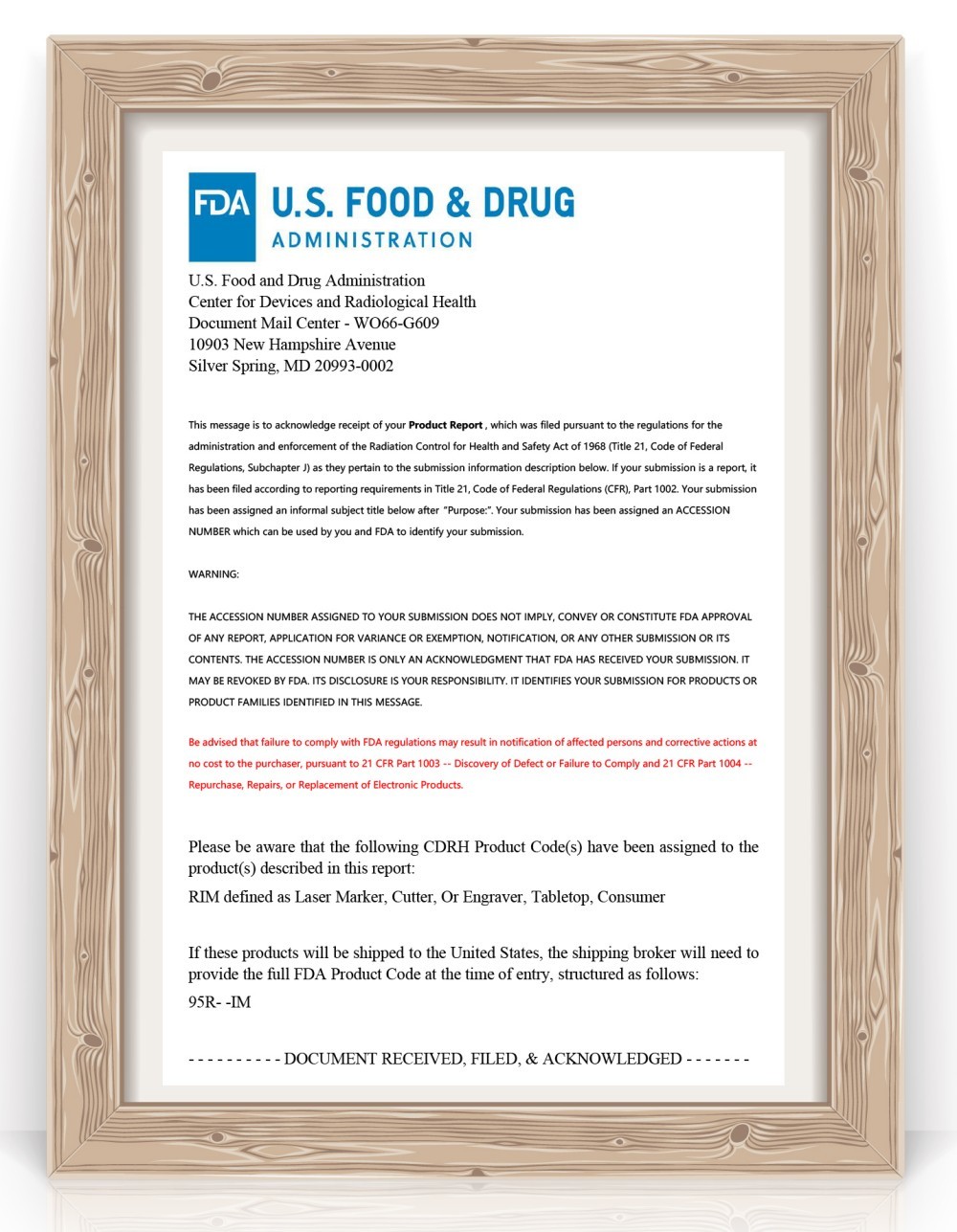

Honor & Certificates

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices. Our cooperated manufacturers have obtained CE, ISO9001 certificates.

Exhibition & Cooperation

Our cooperated manufacturers have obtained C E, I S O 9 0 0 1 certificates. Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as north and south America, Africa, Europe . We also welcome O E M and O D M orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements and we are glad to send you more details and help you choose the most suitable products.

FAQ

Q1. What API can be used to connect to the printer?

A: We will provide a pre-installed RIP software driver on your control computer. You can use your own software to call this editing module to generate print data, thereby enabling connection and printing. In other words, our RIP software handles the editing and compiling of print data, while your software manages user interaction and functional control.

Q2. About the API documentation

A: Once we formally establish cooperation, we will provide complete API documentation to facilitate your development work. Throughout the collaboration, we will also continuously refine the API based on your requirements to ensure a smoother and faster software integration

Q3. Computer connections: Ethernet, USB, or third-party cards (IPipe or MiniG)

A: Our software uses Ethernet communication. The computer and printing unit are connected via a 10-gigabit optical port to transmit print data, ensuring timely data transfer.

Q4. Who should we contact for API integration support?

A:After cooperation is established, we will form a professional team to work with you, including hardware engineers, software engineers, structural engineers, and sales consultants.

Q5. Available testing tools

A:After purchasing the development kit, we will provide specialized testing software to help you better understand the software’s operational logic.