VZJET High-Speed Adjustable Frequency Automatic Sheet Feeder

VZJET High-Speed Auto Frequency-Conversion Sheet Feeder

Message Inquiry

Product Details

Product Overview

An automatic sheet separation device that achieves efficient, automated stacking and separation through the collaborative operation of a feeding roller and a separation mechanism. Widely applied in printers, copiers, and multifunction devices, this equipment optimizes productivity for sheet-like materials and packaged items.

Working Principle

- Mechanical Coordination: The feeding roller and separation mechanism work in tandem to drive stacked items forward.

- Friction Enhancement: Specially designed rough rubber pads increase friction, ensuring stable and precise separation of each sheet.

- Reliability Design: The structure minimizes paper jams, enabling continuous, error-free operation for prolonged use.

Structure & Materials

| Component | Description |

| Main Frame | High-strength hard plastic (injection-molded), balancing durability and lightweight design. |

| Core Separation Components | Rubber pads with optimized friction coefficients for superior separation efficiency. |

| Drive System | Precision gear sets combined with motors for stable, low-noise operation. |

Application Fields

- Printing & Office Equipment:

- Printing Industry:

- Packaging Production Lines:

- Card Processing:

Product Advantages

- Enhanced Efficiency:

- Cost-Effective Operation:

- Wide Adaptability:

- Reliability & Longevity:

Technical Specifications

- Separation Speed: Adjustable (dependent on material type)

- Material Thickness Range: 0.1–1.5 mm

- Power Supply: [Specify voltage & frequency]

Company Reality

Wuhan VZ Information Technology Co., Ltd., established in 2018 , and located in Wuhan, China with convenient transportation accesses , is a professional company engaged in the sale and service of mini color inkjet printers, inkjet printers, continuous inkjet printers, laser marking machines, and the relevant ink consumables. We have a wide range of coding and marking machines to meet customers' different needs in their applications and at the same time, we are making great efforts to develop new products to meet different requirements. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices.

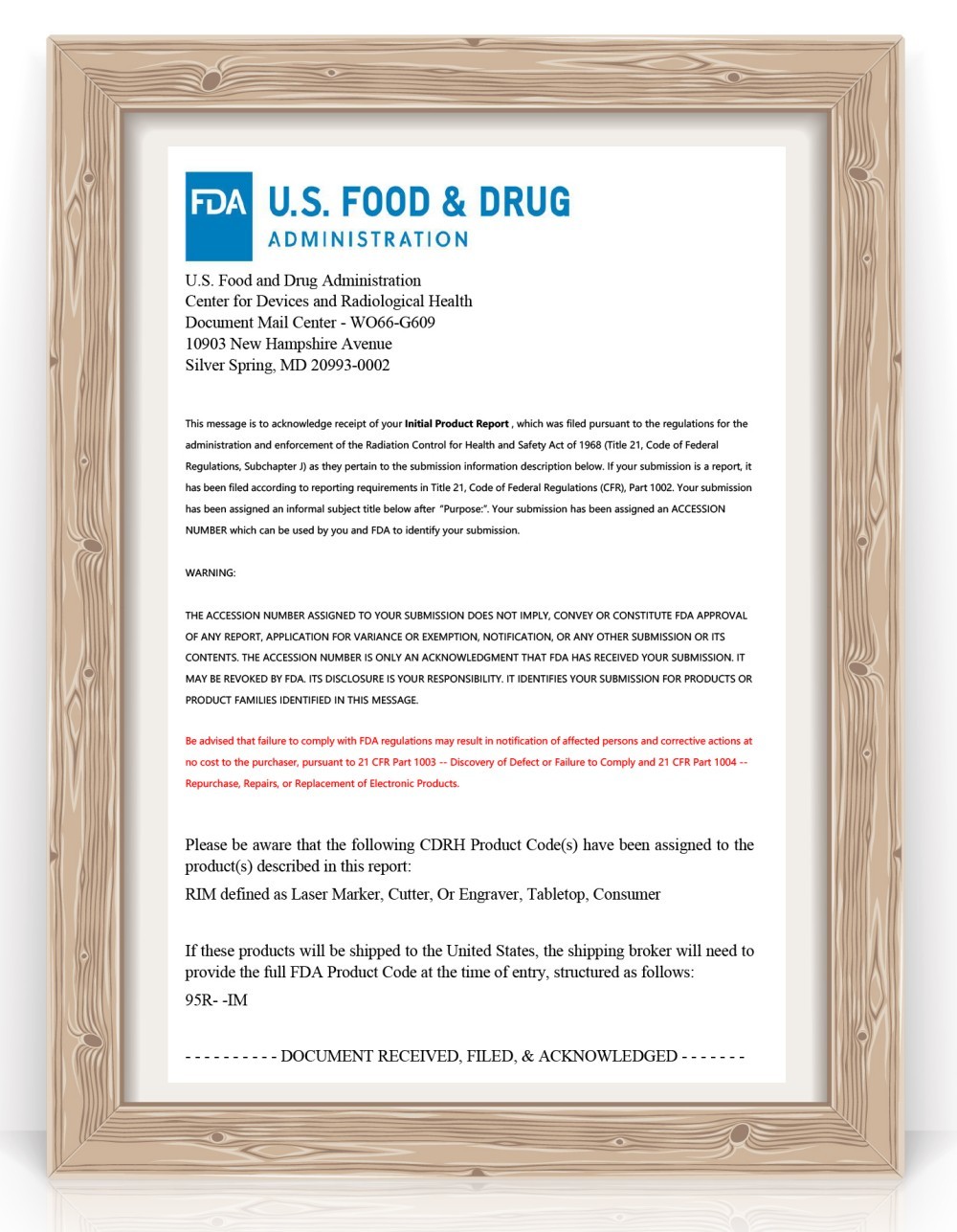

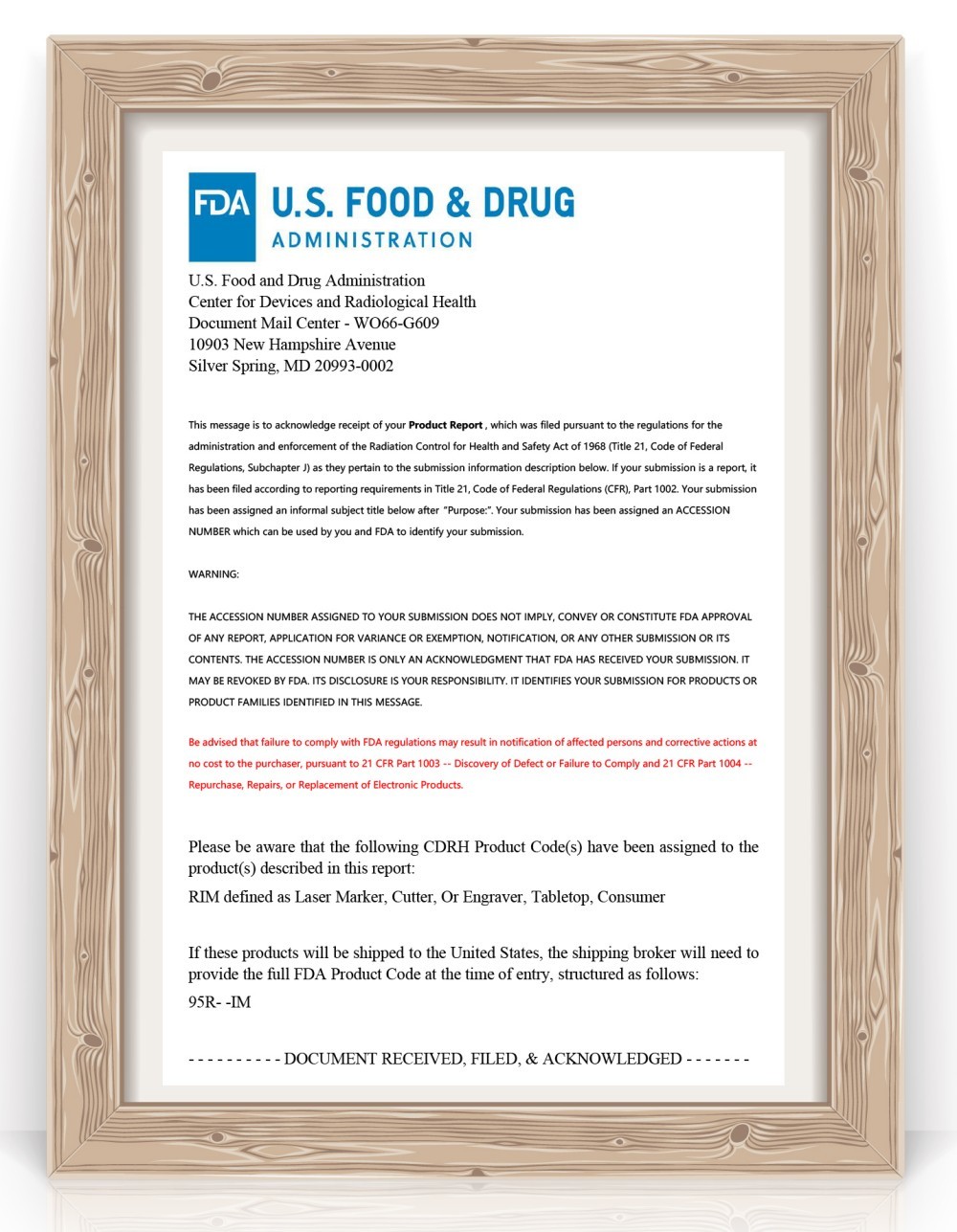

Honor & Certificates

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices. Our cooperated manufacturers have obtained CE, ISO9001 certificates.

Exhibition & Cooperation

Our cooperated manufacturers have obtained C E, I S O 9 0 0 1 certificates. Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as north and south America, Africa, Europe . We also welcome O E M and O D M orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements and we are glad to send you more details and help you choose the most suitable products.

FAQ

Q1. What API can be used to connect to the printer?

A: We will provide a pre-installed RIP software driver on your control computer. You can use your own software to call this editing module to generate print data, thereby enabling connection and printing. In other words, our RIP software handles the editing and compiling of print data, while your software manages user interaction and functional control.

Q2. About the API documentation

A: Once we formally establish cooperation, we will provide complete API documentation to facilitate your development work. Throughout the collaboration, we will also continuously refine the API based on your requirements to ensure a smoother and faster software integration

Q3. Computer connections: Ethernet, USB, or third-party cards (IPipe or MiniG)

A: Our software uses Ethernet communication. The computer and printing unit are connected via a 10-gigabit optical port to transmit print data, ensuring timely data transfer.

Q4. Who should we contact for API integration support?

A:After cooperation is established, we will form a professional team to work with you, including hardware engineers, software engineers, structural engineers, and sales consultants.

Q5. Available testing tools

A:After purchasing the development kit, we will provide specialized testing software to help you better understand the software’s operational logic.