VZJET three-color alarm indicator light LED warning light

VZJET three-color alarm indicator light LED machine tool alarm device signal light multi-layer warning light

Message Inquiry

Product Details

With the continuous advancement of technology, people's demand for automated and intelligent equipment is increasing. Among them, warning lights, as a common device, not only serve as independent work indicators but can also be linked with other equipment to achieve more efficient work processes and enhance production efficiency.

IBasic Principles of Three-color Warning Lights

Three-color warning lights are usually composed of red, yellow and green bulbs. They convey different warning signals by controlling the on-off and flashing of the bulbs. The bulbs can be controlled to turn on or off by connecting or disconnecting the current, and different combinations are used to represent different states and warning information. Such warning lights are typically applied in industrial production sites, traffic management and equipment operation scenarios.

The interlocking methods of two-color and three-color warning lights with other equipment

Sensor interlock

Three-color warning lights can be linked with various sensors, and their lighting, extinguishing and flashing can be triggered by the signals detected by the sensors. For instance, on an industrial production line, by connecting with sensors for temperature, humidity, pressure, etc., when the sensors detect abnormal conditions, the warning lights can promptly issue an alarm to alert the operators. This linkage method not only enhances the safety of the production line but also helps to detect and solve problems in a timely manner, preventing accidents from happening.

Controller linkage

The three-color warning light can be connected to a controller to interact with other devices. For instance, in traffic signals, the warning light can be linked to a controller to switch between different colors based on traffic flow and the status of the signal light. On the operation panel of construction machinery, the warning light can be connected to a controller to indicate the machine's working status and issue abnormal alarms. This interactive approach enables operators to have a more intuitive understanding of the equipment's status when using it, enhancing work efficiency and safety.

PLC-controlled interlocking

The three-color warning light can be linked with the PLC (Programmable Logic Controller). The PLC is a device specifically designed for automation control, which regulates and controls the operation status of various devices by programming input and output signals. The three-color warning light can be connected to the PLC through the PLC interface, and the on-off and flashing of the warning light can be controlled according to the operation logic and program of the PLC. This linkage method enables the warning light to work according to the control logic of the system, achieving more intelligent operation.

Advantages of the Three-color Warning Light Linking with Other Equipment

Improve safety and visibility

By interacting with other devices, the warning lights can issue alerts based on the system's operational status and abnormal conditions. This enhances workplace safety, enables timely detection and resolution of issues, and helps prevent accidents. Additionally, the on/off and flashing of the warning lights improve the visibility of the equipment, allowing operators to promptly notice the warning signals and take appropriate actions.

2. Enhance work efficiency and production efficiency

The interconnection of warning lights with other equipment can achieve automated and intelligent workflow. Through the interconnection of sensors, controllers, and PLCs, warning lights can automatically issue alerts and instructions based on the system's working status. This can reduce the need for human intervention, improve work efficiency, decrease errors and accidents, and enhance production efficiency.

Application Scenarios of Three-color Warning Lights in Coordination with Other Equipment

Industrial production line

On industrial production lines, warning lights, in conjunction with sensors and controllers, monitor the status and operation of production equipment in real time, promptly detecting and addressing faults and abnormal conditions.

Equipment operation panel

On the operation panels of various devices, through the interlocking controller and PLC, warning lights can indicate the working status of the equipment and abnormal alarms, facilitating the operators to promptly understand the equipment conditions and take corresponding measures.

Summary: The three-color warning light is a common warning device. Based on its basic principle, it can achieve more intelligent and automated work processes through interaction with other devices. By interacting with sensors, controllers, and PLCs, etc., the warning light can monitor the status of equipment and abnormal situations in real time, enhancing safety, visibility, and work efficiency. In scenarios such as industrial production lines, traffic management, and equipment operation, the application of three-color warning lights in conjunction with other devices is very widespread, playing a significant role in optimizing work processes and improving production efficiency.

Company Reality

Wuhan VZ Information Technology Co., Ltd., established in 2018 , and located in Wuhan, China with convenient transportation accesses , is a professional company engaged in the sale and service of mini color inkjet printers, inkjet printers, continuous inkjet printers, laser marking machines, and the relevant ink consumables. We have a wide range of coding and marking machines to meet customers' different needs in their applications and at the same time, we are making great efforts to develop new products to meet different requirements. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices.

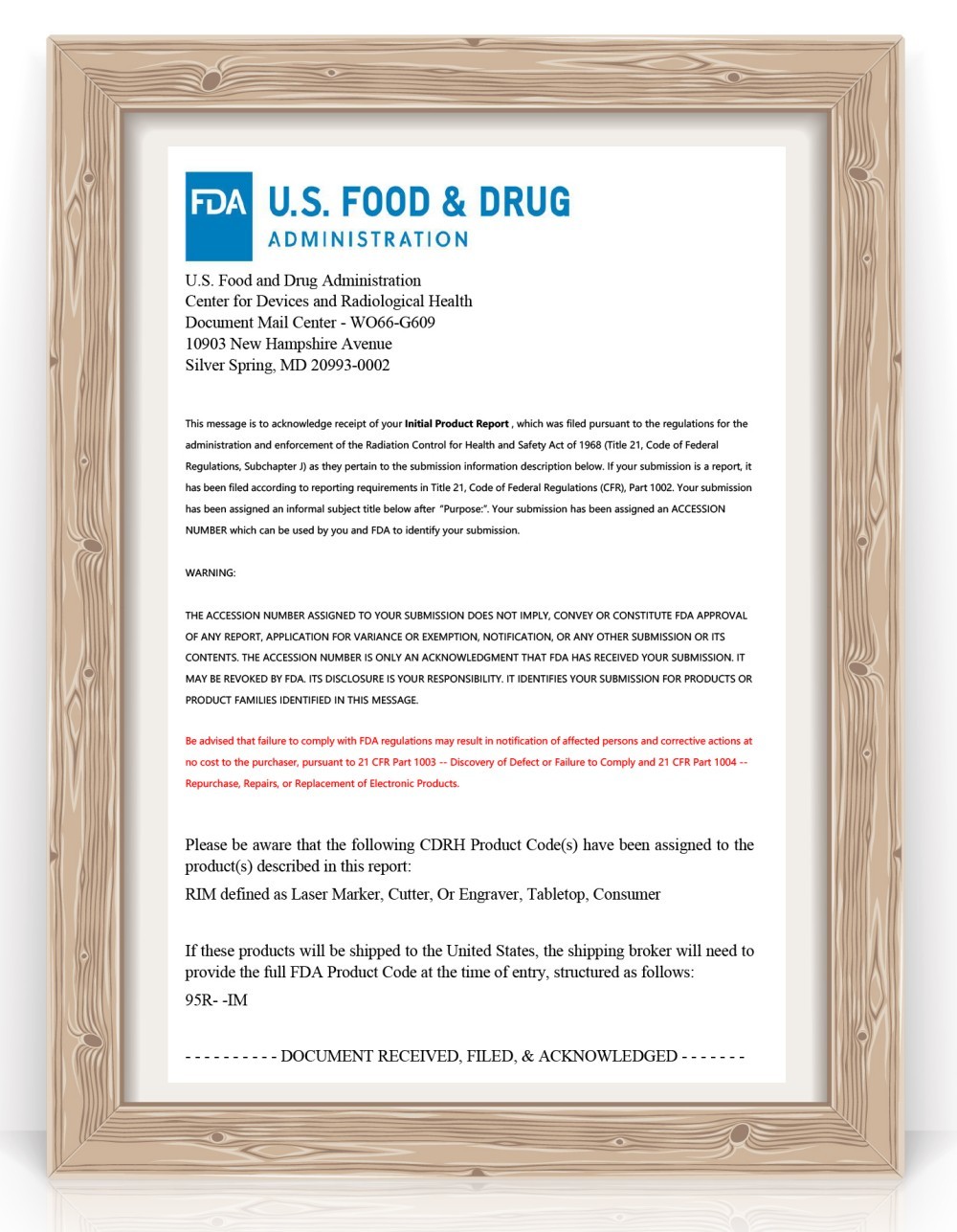

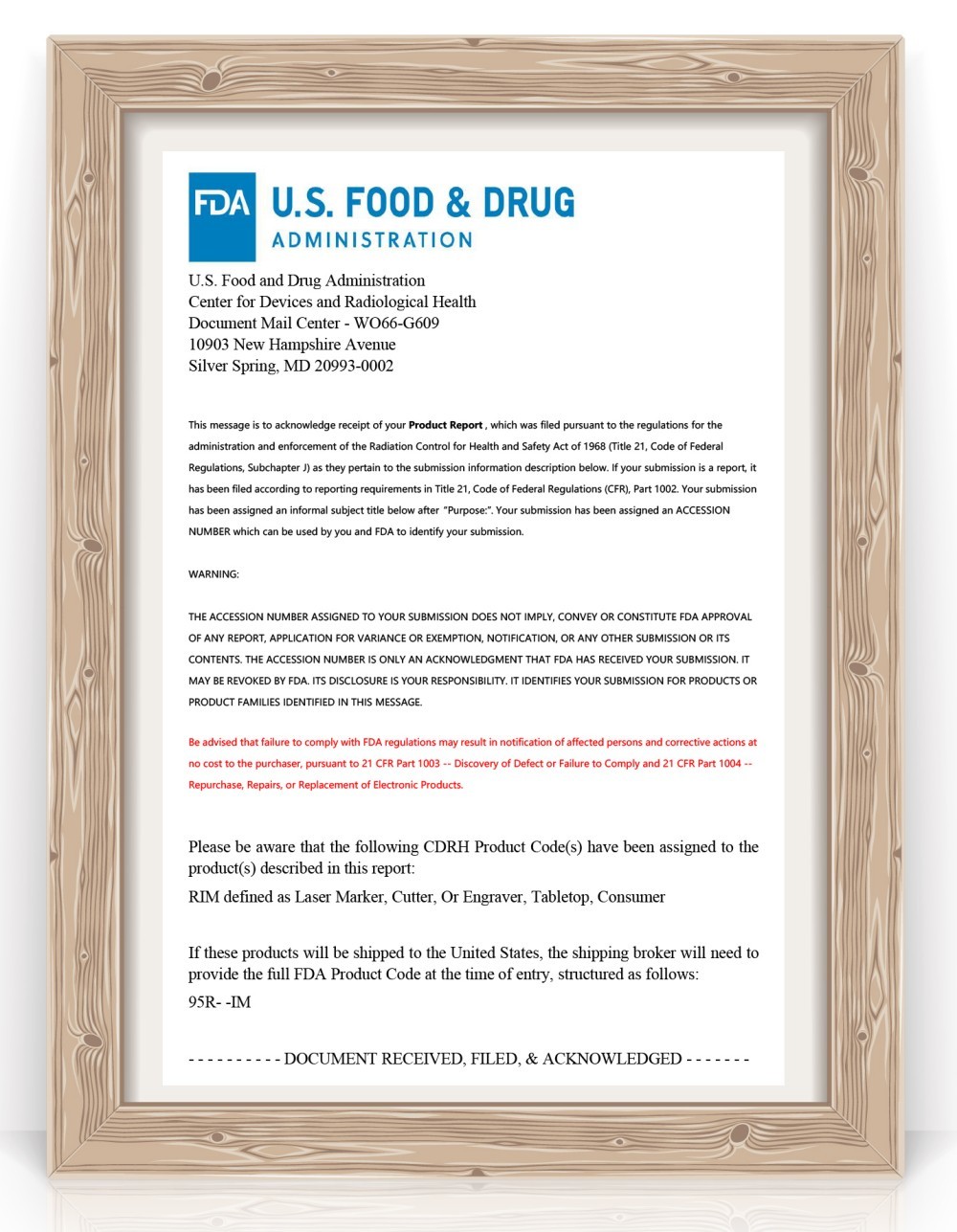

Honor & Certificates

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices. Our cooperated manufacturers have obtained CE, ISO9001 certificates.

Exhibition & Cooperation

Our cooperated manufacturers have obtained C E, I S O 9 0 0 1 certificates. Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as north and south America, Africa, Europe . We also welcome O E M and O D M orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements and we are glad to send you more details and help you choose the most suitable products.

FAQ

Q1. What API can be used to connect to the printer?

A: We will provide a pre-installed RIP software driver on your control computer. You can use your own software to call this editing module to generate print data, thereby enabling connection and printing. In other words, our RIP software handles the editing and compiling of print data, while your software manages user interaction and functional control.

Q2. About the API documentation

A: Once we formally establish cooperation, we will provide complete API documentation to facilitate your development work. Throughout the collaboration, we will also continuously refine the API based on your requirements to ensure a smoother and faster software integration

Q3. Computer connections: Ethernet, USB, or third-party cards (IPipe or MiniG)

A: Our software uses Ethernet communication. The computer and printing unit are connected via a 10-gigabit optical port to transmit print data, ensuring timely data transfer.

Q4. Who should we contact for API integration support?

A:After cooperation is established, we will form a professional team to work with you, including hardware engineers, software engineers, structural engineers, and sales consultants.

Q5. Available testing tools

A:After purchasing the development kit, we will provide specialized testing software to help you better understand the software’s operational logic.