VZJET Synchronous Encoder

synchronous encoder is a high-precision position and speed detection device

Message Inquiry

Product Details

Synchronous Encoder Product Details

Product Overview

A synchronous encoder is a high-precision position and speed detection device that achieves closed-loop control of motion systems by real-time capturing angular displacement signals of rotating components and converting them into electrical signals. It is widely used in industrial automation, robotics, CNC machine tools, and other fields to ensure operational stability and positioning accuracy of equipment.

Working Principle

- Signal Acquisition: Scans the scale of the encoder disc (or magnetic ring) through photoelectric induction (or magnetoelectric induction) to generate periodic pulse signals.

- Synchronous Output: Output signals are strictly synchronized with the motion state of the motor or rotating shaft. Common output types include:

- Incremental (A/B phase pulses, Z phase zero position signal)

- Absolute (multi-turn encoding, directly outputs absolute position values)

- Signal Processing: Pulse signals are amplified and shaped before being transmitted to the controller for position feedback and speed adjustment.

- Incremental (A/B phase pulses, Z phase zero position signal)

- Synchronous Output: Output signals are strictly synchronized with the motion state of the motor or rotating shaft. Common output types include:

Key Technical Parameters

| Parameter Type | Description |

| Resolution | Common range: 100–5000 PPR (Pulses Per Revolution), supports customized high resolution (e.g., 10000 PPR). |

| Output Signal | TTL, HTL, RS422, sine wave (Sin/Cos), etc., compatible with mainstream controller interfaces. |

| Operating Voltage | DC 5V, DC 12–24V (optional by model), with strong resistance to power fluctuations. |

| Maximum Speed | Typically ≤6000 RPM; high-speed models reach 10000 RPM, adapting to different working conditions. |

| Protection Class | Housing with IP54/IP65 protection, dust and liquid splash-proof, suitable for harsh industrial environments. |

Application Fields

- Industrial Automation: Servo motor control, production line drive systems, robotic arm positioning.

- CNC Machine Tools: Position feedback for main shafts and feed shafts to ensure machining accuracy.

- Robotics: Joint motion detection for precise trajectory control.

- New Energy Equipment: Wind turbine pitch control, solar tracking systems.

- Aerospace: Flight attitude sensors, precision pan-tilt adjustment.

Product Advantages

- High-Precision Feedback: Adjustable resolution, positioning error ≤±1 pulse, meeting micron-level control requirements.

- Anti-Interference Design: Built-in shielding layer and differential signal output effectively suppress electromagnetic interference (EMI).

- Long Service Life: Metal encoder shaft and wear-resistant bearings ensure mean time between failures (MTBF) ≥30,000 hours.

- Flexible Adaptation: Supports multiple installation methods (flange type, bushing type) for compatibility with different mechanical structures.

- Real-Time Synchronization: Signal delay ≤1ms ensures dynamic response and system synchronization.

Structure and Materials

- Housing: Aluminum alloy/stainless steel with anti-oxidation treatment for strong corrosion resistance.

- Code Disc: Glass disc (high-precision models) or metal disc (impact-resistant models), with line engraving accuracy ±5μm.

- Interface: Aviation plug or cable outlet, supports customized waterproof connectors.

Selection Recommendations

- For dynamic high-speed response, recommend incremental + sine wave output models.

- For power-off position memory, recommend absolute multi-turn encoders (e.g., 17-bit, 23-bit encoding).

- In harsh environments (high temperature, dust), suggest magnetoelectric encoders (no optical components, strong anti-pollution capability).

Company Reality

Wuhan VZ Information Technology Co., Ltd., established in 2018 , and located in Wuhan, China with convenient transportation accesses , is a professional company engaged in the sale and service of mini color inkjet printers, inkjet printers, continuous inkjet printers, laser marking machines, and the relevant ink consumables. We have a wide range of coding and marking machines to meet customers' different needs in their applications and at the same time, we are making great efforts to develop new products to meet different requirements. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices.

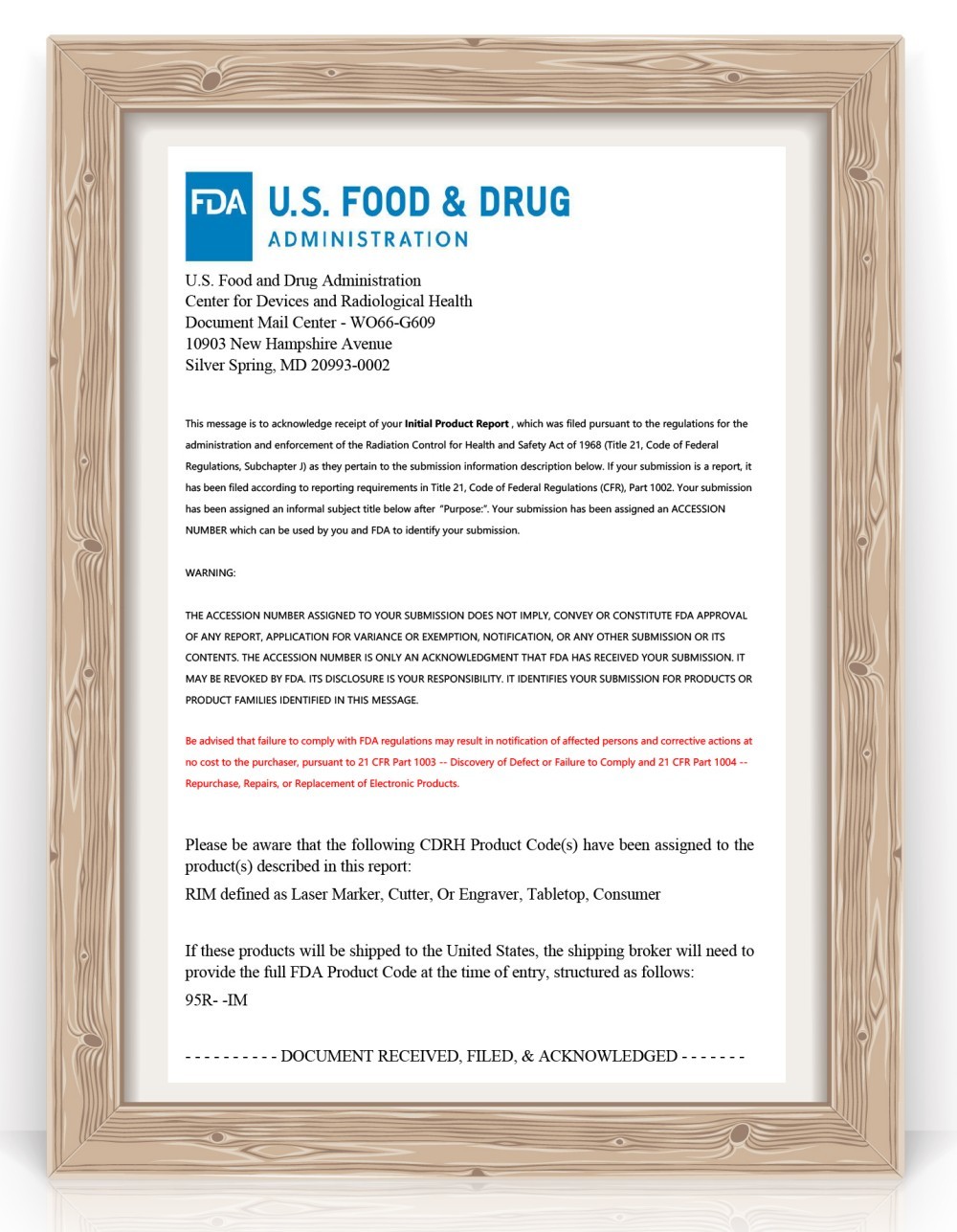

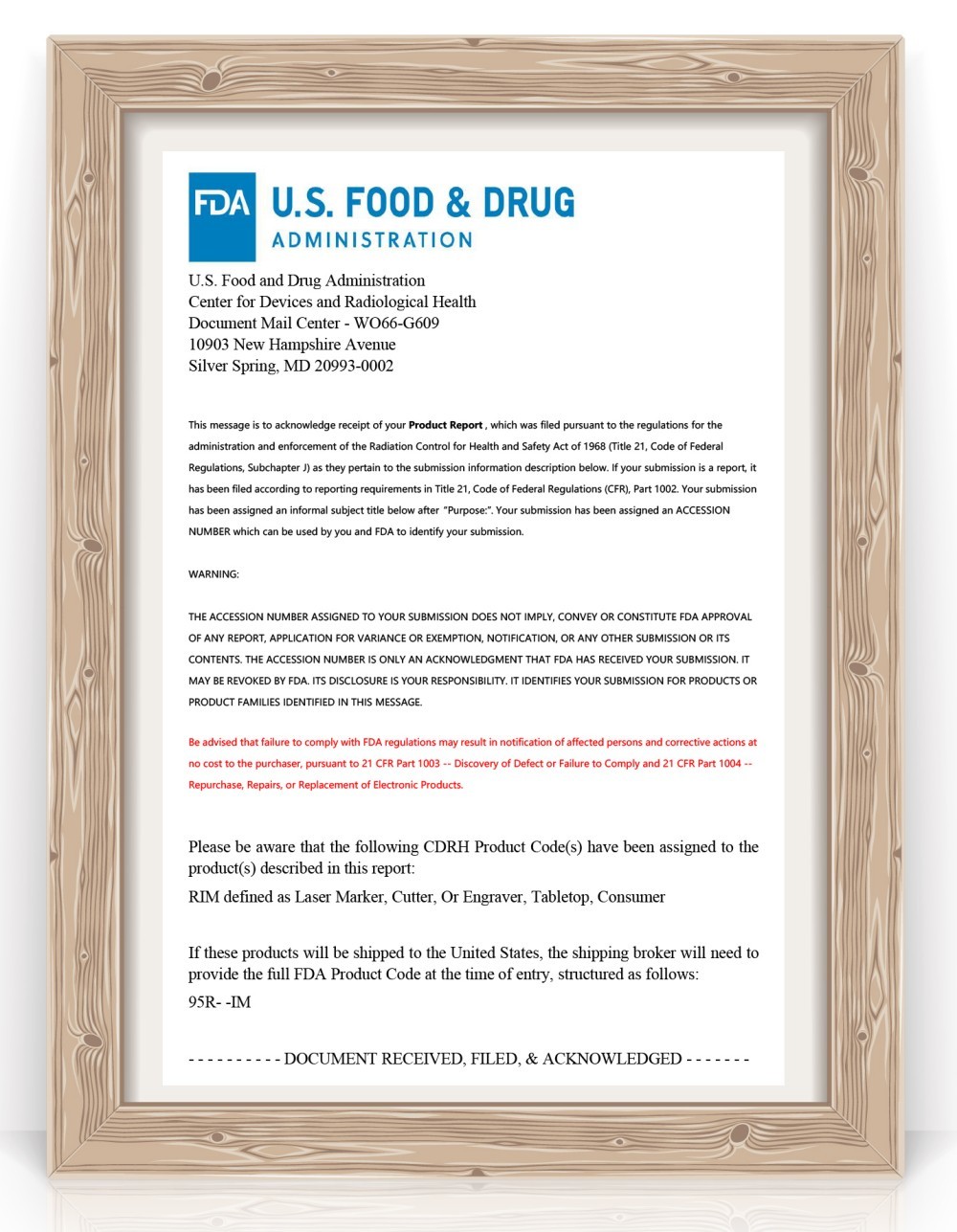

Honor & Certificates

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality products and competitive prices. Our cooperated manufacturers have obtained CE, ISO9001 certificates.

Exhibition & Cooperation

Our cooperated manufacturers have obtained C E, I S O 9 0 0 1 certificates. Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as north and south America, Africa, Europe . We also welcome O E M and O D M orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements and we are glad to send you more details and help you choose the most suitable products.

FAQ

Q1. What API can be used to connect to the printer?

A: We will provide a pre-installed RIP software driver on your control computer. You can use your own software to call this editing module to generate print data, thereby enabling connection and printing. In other words, our RIP software handles the editing and compiling of print data, while your software manages user interaction and functional control.

Q2. About the API documentation

A: Once we formally establish cooperation, we will provide complete API documentation to facilitate your development work. Throughout the collaboration, we will also continuously refine the API based on your requirements to ensure a smoother and faster software integration

Q3. Computer connections: Ethernet, USB, or third-party cards (IPipe or MiniG)

A: Our software uses Ethernet communication. The computer and printing unit are connected via a 10-gigabit optical port to transmit print data, ensuring timely data transfer.

Q4. Who should we contact for API integration support?

A:After cooperation is established, we will form a professional team to work with you, including hardware engineers, software engineers, structural engineers, and sales consultants.

Q5. Available testing tools

A:After purchasing the development kit, we will provide specialized testing software to help you better understand the software’s operational logic.